PEDOT:PSS and PEDOT dispersions for a range of applications

PEDOT:PSS, or Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate, is a transparent conductive polymer consisting of a mixture of the ionomers poly(3,4-ethylenedioxythiophene) and polystyrene sulfonate. Due to its unique combination of conductivity, transparency, ductility, and ease of processing, PEDOT:PSS has become a benchmark material in thin-film electronic fabrication.

Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate can be used as an interfacial layer for hole transport in organic light emitting diodes, organic photovoltaics, and perovskite photovoltaics. It can also be used as a replacement for transparent conductors such as ITO or FTO and is used commonly in applications where the underlying substrate is flexible.

Ossila supplies a range of PEDOT:PSS and PEDOT dispersions that are suitable for different applications.

AI 4083

Order code M121

Deep work function of 5.0 - 5.2 eV

For interfacial layers in photovoltaic (OPV) and light emitting diodes (OLED)

£176

PH 1000

Order code M122

High conductivity and optical transparency

For high conductivity films and interfacial layers

£176

HTL Solar

Order code M124

Improved wetting properties, particularly in inverted OPV cells

For surfaces that are difficult to wet with an aqueous dispersion

£176

HTL Solar 3

Order code M125

Uses an alternative counter ionomer to PSS to allow for the dispersion in toluene

For use with perovskite materials and whenever water-based dispersion is problematic

£196

PEDOT:PSS typically comes as a water based emulsion which is created via the polymerization of PEDOT monomers in a polystyrene sulfonic acid solution. We supply all our PEDOT:PSS solutions in light resistant bottles with temperature indicators.

Properties

The properties of PEDOT:PSS vary from dispersion to dispersion, hence its versatility. The key properties of PEDOT:PSS are the extent to which it is conductive and the size of its work function. Since PEDOT is conductive and PSS insulating, the conductivity of the resulting polymer depends on ratio between these two ionomers and the microstructure of the film. Similarly, a higher presence of PSS at the surface will result in a deeper work function.

Applications

PEDOT:PSS is used for a range of applications within thin-film electronic fabrication, including:

- Perovskite photovoltaics

- Organic photovoltaics

- Organic electrochemical transistors

- Flexible electronics

- Organic light emitting diodes

- Transparent conductors

- Thermoelectric generators

- Supercapitors and energy storage

Substrate surfaces should be prepared before the deposition of PEDOT:PSS to ensure that they are clean. This can be done using DI water, Hellmanex iii, isopropyl alcohol and a UV Ozone Cleaner. Once the surface is ready, a spin coater can be used to create a PEDOT:PSS thin film.

Please see the "usage" tab for more information.

What Makes PEDOT:PSS Conductive?

The electrical conductivity of oxidized polythiophenes has been known about for nearly 40 years. The origins of this conductivity are due to the presence of radical states which are formed due to the oxidation of the thiophene units. These reduced states are delocalized across the polymer chain, and in the presence of the oxidizer these radicalized states can be stabilized. In PEDOT:PSS the PEDOT is oxidized during the polymerisation reaction by the polystyrene sulfonate. This produces an emulsion where the PSS present stabilizes the radical states on the PEDOT.

Although PEDOT itself is conductive, the PSS present within the blend is insulating. The quantity of PSS and the microsctructure of the film therefore have a significant impact on the electronic properties of PEDOT:PSS. In a water based dispersion the PEDOT and PSS form a micelle structure in which the hydrophobic PEDOT core is surrounded by a shell of hydrophilic PSS. During deposition this structure is retained forming localized regions of conductive PEDOT surrounded by insulating regions of PSS. It is this core-shell structure which results in the low conductivity values that can arise for standard formulations of PEDOT:PSS.

Can the Conductivity of PEDOT:PSS be Improved?

Advanced formulations offer increased conductivity of PEDOT:PSS thin films. This is achieved by the addition of secondary solvents (sometimes referred to as secondary dopants) to the solution or exposing thin films to these secondary solvents.

It was originally believed that these solvents acted by further doping the PEDOT, hence the name secondary dopant. More recent work has revealed that their presence changes the core-shell structure that is normally seen. When exposed to these solvents the hydrophilic/hydrophobic nature of the PSS/PEDOT components no longer determine the structure. The solvents allow the diffusion and intermixing of the PEDOT and PSS chains creating a more homogenous film on the microscale. This homogenisation increases the path length of charges along the PEDOT chain reducing the distance that charges must travel across PSS rich areas.

What Determines the Work Function of PEDOT?

As work function is a surface property of a material the work function of the PEDOT:PSS blend will be determined by the percentage of each component at the surface of the film. PSS has a significantly deeper work function than PEDOT, therefore a higher presence of PSS at the surface will result in a deeper work function. This means that for formulations with higher percentages of PSS, the work function will be higher than those with lower percentages.

In addition, the processing of the PEDOT:PSS film can result in changes to the work function. When PEDOT:PSS forms a core-shell structure, PEDOT is surrounded by PSS. In this case the work function will be dominated by PSS. If the film has been treated such that the components are more homogenously dispersed, however, the work function will become more shallow as the surface becomes richer with PEDOT.

How Should PEDOT Materials be Stored?

The recommended storage temperature of PEDOT:PSS dispersions is 5 - 10 degrees Celsius. Therefore it is recommended that you store the dispersion at the front of a refrigerator. The product is not usable if frozen and should therefore should be kept away from the back of the refrigerator (where it is coldest).

The dispersions can tolerate a few days to a week outside of the refrigerator (e.g. during shipping) without negative consequences on the PEDOT:PSS performance. Over time at elevated temperatures, the PEDOT:PSS can phase separate, aggregate and form a solid that drops to the bottom of the bottle, reducing performance. Brief heating to a max. of 50°C however has no adverse effect on product properties.

What is the Shelf Life of PEDOT Materials?

When stored at 5 - 10 degrees Celsius, the PEDOT:PSS dispersion will give you consistent performance over 12 months when used regularly. The official recommended shelf life from the manufacturer is 9 months after production, if the dispersion is never used or disturbed. After this time, the dispersion will gradually separate/sediment out at a very slow rate, resulting in lower concentrations and ultimately thinner films.

This degradation is mitigated by frequent use of the dispersion due to the gentle agitation caused when decanting. Through constant use, it is possible to use a single bottle of PEDOT:PSS for many years without harming device performance.

PEDOT:PSS (AI 4083)

Heraeus Clevios™ AI 4083 is one of the most commonly used PEDOT:PSS formulations, due to its deep work function it is often used for matching of interfacial energy levels in thin film electronic devices.

AI 4083 specifications and MSDS

| Resistivity | 500-5000 Ω.cm |

| Solid content | 1.3 to 1.7 wt.% (in water) |

| Viscosity | 5-12 mPa.s |

| PEDOT:PSS ratio | 1:6 |

| Particle Size Distribution | D90 = 100nm; D50 = 80nm |

| Work function | 5.0 - 5.2 eV |

| CAS number | 155090-83-8 |

| Packaging | 100 ml of solution sealed in a light resistant bottle with temperature indicator |

PEDOT:PSS (PH 1000)

Heraeus Clevios™ PH1000 PEDOT:PSS is designed for applications where high conductivity and optical transparency are required. The potential uses for high conductivity PEDOT:PSS formulations include replacements for ITO, semitransparent top electrodes in thin film electronics, top gate electrodes in FETs, and for use as a thick planarisation layer on rough surfaces such as FTO. Sheet resistances as low as 300 Ω/square can be achieved with the addition of conductivity enhancement agents such as dimethylsulfoxide and ethylene glycol.

PH 1000 specifications and MSDS

| Resistivity | <0.0012 Ω.cm* |

| Solid content | 1.0 - 1.3 wt.% (in water) |

| Viscosity | < 50 mPa.s |

| PEDOT:PSS ratio | 1:2.5 |

| Particle Size Distribution | D50 = 30nm |

| Work Function | 4.8 - 5.0 eV |

| CAS number | 155090-83-8 |

| Packaging | 100 ml of solution sealed in a light resistant bottle with temperature indicator |

*With use of 5% DMSO by volume as a morphology enhancer

PEDOT:PSS (HTL Solar)

Heraeus Clevios™ HTL Solar is a PEDOT:PSS formulation designed for use in thin film electronics as an interfacial material. The advantage of the HTL Solar formulation is its improved wetting properties, particularly in inverted OPV cells, compared to the other PEDOT:PSS formulations in our catalogue.

HTL Solar specifications and MSDS

| Resistivity | 1 - 10 Ω.cm |

| Solid content | 1.0 - 1.3 wt.% (in water) |

| Viscosity | 8 to 30 mPa.s |

| PEDOT:PSS ratio | 1:2.5 |

| Work Function | 4.8 - 5.0 eV |

| CAS number | 155090-83-8 |

| Packaging | 100 ml of solution sealed in a light resistant bottle with temperature indicator |

PEDOT:complex (HTL Solar 3)

Heraeus Clevios™ HTL Solar 3 is a PEDOT formulation using a alternative counter ionomer to PSS to allow for the dispersion in toluene. HTL Solar 3 is ideal for use with materials or in environments that are water sensitive, such as in glove box environments or for use with perovskite materials.

HTL Solar 3 specifications and MSDS

| Resistivity | 5-500 Ω.cm |

| Solid content | 1.5 to 2.5 wt.% (in toluene <0.5% water) |

| Viscosity | <10 mPa.s |

| PEDOT:PSS ratio | N/A |

| Work function | 4.4eV - 4.8eV |

| CAS number | 155090-83-8 |

| Packaging | 2 x 25 ml of solution sealed in a light resistant bottles with temperature indicator |

Applications

A considerable amount of research has been done into the applications of PEDOT:PSS.Perovskite photovoltaics

PEDOT:PSS has been used as a hole extraction material in inverted devices in order to facilitate the extraction of charge carriers at the interface between the transparent conductive oxide and the active perovskite layer. Inverted perovskite devices using PEDOT:PSS typically show lower hysteresis than standard architecture devices. In addition recent work on standard architecture devices show that the toluene based PEDOT:PSS can be used as a cheap alternative to spiro-OMeTAD.

Organic photovoltaics

PEDOT:PSS has long been used as a standard material in device fabrication, it has been extensively used with materials such as P3HT and PCDTBT to form the backbone of fundamental research into polymer solar cells. In addition PEDOT:PSS is still used in combination with the state of the art organic photovoltaic materials to push new efficiency limits.

Organic light emitting diodes

The use of PEDOT:PSS in organic light emitting diodes has been widespread for over a decade now and is a well established standard hole injection material. More recent work still uses PEDOT:PSS due to its deep work function allowing for efficient charge injection into white emitting polymers and also host materials for thermaly activated delayed fluorescence materials.

Transparent conductors

PEDOT:PSS has been seen as a potential replacement for expensive transparent metal oxides such as ITO and FTO and has been shown in both organic photovoltaic and perovskite photovoltaic devices to be an effective replacement. In addition, in combination with metallic grid structures sheet resistances comparable to metallic films are possible.

Surface Preparation

For preparation of the surface of a substrate for deposition of PEDOT:PSS you will need the following products: FTO Glass/ITO Glass/Glass/SiO2 substrate, 1.1mm Substrate Rack/2.2mm Substrate Rack (product coming soon), Hellmanex iii, isopropyl alcohol, and UV Ozone Cleaner.

Learn More About the Ossila UV Ozone Cleaner

- Ultraclean surfaces within minutes

- Does not cause damage to the sample

- Simple to use, and with a large cleaning area

- Just £1950 with FREE worldwide shipping

Find out more

The following is a step-by-step guide for preparing surfaces for the deposition of PEDOT:PSS, an instructional video is provided below.

- Sonicate chosen substrate for 5 minutes in hot (70°C) DI water with the addition of 1% Hellmanex

- Dump-rinse twice in boiling DI water

- Sonicate chosen substrate for 5 minutes in Isopropyl alcohol

- Dump-rinse twice in boiling DI water

- Dry chosen substrate using filtered compressed gas

- Place the chosen substrate into the UV Ozone cleaner and leave for 10 minutes

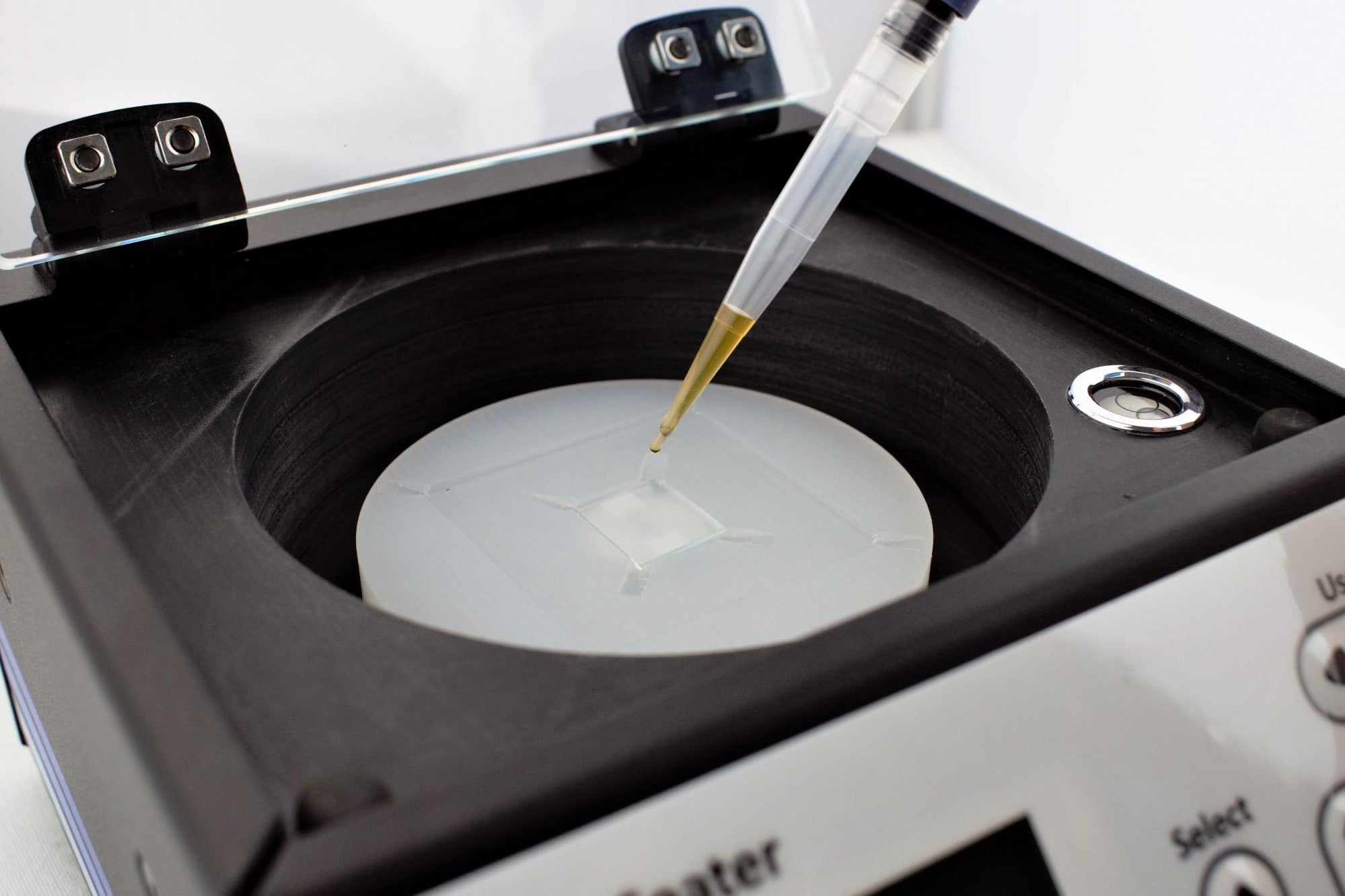

Thin-Film Deposition of PEDOT:PSS

For the deposition of thin films of PEDOT:PSS on a freshly prepared surface you will need the following products: FTO Glass/ITO Glass/Glass/SiO2 Substrate, Amber Vial, 0.45 µm PES filter, Solvent Safe Syringe, PEDOT:PSS, Micropipette, Spin Coater, and Hot Plate.

- Filter your PEDOT:PSS solution through the 0.45 µm PES filter into an amber vial (if using HTL Solar 3 use a 0.45 µm PTFE (hydrophobic) filter).

- Preheat the hot plate to 120°C

- Place a freshly prepared substrate into the spin coater and set to the desired spin speed.

- For speeds below 1000 rpm we recommend static spin coating or the solution for higher speeds dynamic spin coating can be done.

- The substrates should be spun until the films are dry, for PEDOT:PSS films this is typically >30s.

- Once the spin coating has finished place the samples on the hotplate for 15 minutes to fully dry.

Get the Ossila Spin Coater

- Designed for the lab: vacuum-free, compact and portable

- The ultimate plug-and-play spin coater

- Spin speeds range from 120 to 6000 rpm

- Just £1950 with FREE worldwide shipping

Find out more

Obtaining a Uniform Coating

The coating quality of the PEDOT:PSS will be dependent upon several factors. These include the PEDOT formulation you are using, the deposition technique, the surface you are depositing onto and the cleanliness of the surface.

Ideally, the film should be highly uniform across the entire surface with possible variations at the ends of your sample due to edge effects. Sometimes due to the wetting conditions of the PEDOT formulation on the surface, the coating may not be uniform. If this occurs there are several things that can be done. The first is to ensure that the surface of your sample is clean, if possible use a combination of solvent cleaning steps and UV ozone or oxygen plasma treatments (as described above) to ensure a completely clean surface.

If this does not improve the quality of the surface, secondary solvents can be added. For AI 4083 and PH1000 the addition of approximately 10% isopropanol can improve the wetting on surfaces.

Literature

Perovskite photovoltaics

- Efficient organometal trihalide perovskite planar-heterojunction solar cells on flexible polymer substrates, H. J. Snaith et. al. Nature Communications, 4, (2013) DOI: 10.1038/ncomms3761

- High efficiency stable inverted perovskite solar cells without current hysteresis, M. Grätzel et. al. Energy Environ. Sci. 8, (2015) 2725-2733 DOI: 10.1039/c5ee00645g

- Employing PEDOT as the p-type charge collection layer in regular organic-inorganic perovskite solar cells, H. J. Snaith et. al. J. Phys. Chem. Lett. 6 (9), (2015) 1666-1673 DOI: 10.1021/acs.jpclett.5b00545

Organic photovoltaics

- Nanoscale morphology of high-performance polymer solar cells, R. A. J. Janssen, Nano Lett. 5 (4), (2005) 579-583 DOI: 10.1021/nl048120i

- Bulk heterojunction solar cells with internal quantum efficiency approaching 100%, A. J. Heeger et.al. Nature Photonics, 3, (2009) 297-302 DOI: 10.1038/nphoton.2009.69

- Single-junction organic solar cells based on a novel wide-bandgap polymer with efficiency of 9.7%, Y. Sun et. al. Adv. Mater. 27 (18), (2015) 2938-2944 DOI: 10.1002/adma.201500647

Organic light emitting diodes

- Molecular organic light-emitting diodes using highly conducting polymers as anodes, H. Kafafi et. al. Appl. Phys. Lett. 80, (2002) 3844 DOI: 10.1063/1.1480100

- High-efficiency white-light-emitting devices from a single polymer by mixing singlet and triplet emission, Y. Cao et. al. Adv. Mater. 18, (2006) 1769-1773 DOI: 10.1002/adma.200502740

- A universal host material for high external quantum efficiency close to 25% and long lifetime in green fluorescent and phosphorescent OLEDs, J. Y. Lee et. al. Adv. Mater. 26, (2014) 4050-4055 DOI: 10.1002/adma.201400347

Transparent conductors

- Highly conductive PEDOT:PSS electrode by simple film treatment with methanol for ITO-free polymer solar cells, C. W. Chu et. al. Energy Environ. Sci. 5, (2012) 9662-9671 DOI: 10.1039/C2EE22595F

- Flexible high power-per-weight perovskite solar cells with chromium oxide-metal contacts for improved stability in air, S. Bauer et. al. Nature Materials, 14, (2015) 1032-1039 DOI: 10.1038/nmat4388

- All solution roll-to-roll processed polymer solar cells free from indium-tin-oxide and vacuum coating steps, F. C. Krebs, Org. Electron. 10 (5), (2009) 761-768 DOI: 10.1016/j.orgel.2009.03.009

To the best of our knowledge the technical information provided here is accurate. However, Ossila assume no liability for the accuracy of this information. The values provided here are typical at the time of manufacture and may vary over time and from batch to batch.

About Ossila Founded in 2009 by organic electronics research scientists, Ossila aims to provide the components, equipment, and materials to enable intelligent and efficient scientific research and discovery. Over a decade on, we're proud to supply our products to over 1000 different institutions in over 80 countries globally. With decades of academic and industrial experience in developing organic and thin-film LEDs, photovoltaics, and FETs, we know how long it takes to establish a reliable and efficient device fabrication and testing process. As such, we have developed coherent packages of products and services - enabling researchers to jump-start their organic electronics development program. The Ossila Guarantee Free Worldwide Shipping Eligible orders ship free to anywhere in the world Fast Secure Dispatch Rapid dispatch on in-stock items via secure tracked courier services Quality Assured Backed up by our free two year warranty on all equipment Clear Upfront Pricing Clear pricing in over 30 currencies with no hidden costs Large Order Discounts Save 8% on orders over $10,300.00 and 10% on orders over $12,900.00 Expert Support Our in-house scientists and engineers are always ready to help Trusted Worldwide Great products and service. Have already recommended to many people. Dr. Gregory Welch, University of Calgary Wonderful company with reasonably priced products and so customer-friendly! Shahriar Anwar, Arizona State University The Ossila Team Prof. David Lidzey - Chairman As professor of physics at the University of Sheffield, Prof. David Lidzey heads the university’s Electronic and Photonic Molecular Materials research group (EPMM). During his career, David has worked in both academic and technical environments, with his main areas of research including hybrid organic-inorganic semiconductor materials and devices, organic photonic devices and structures and solution processed photovoltaic devices. Throughout his academic career, he has authored over 220 peer-reviewed papers. Dr. James Kingsley - Managing Director James is a co-founder and managing director of Ossila. With a PhD in quantum mechanics/nanotech and over 12 years’ experience in organic electronics, his work on the fabrication throughput of organic photovoltaics led to the formation of Ossila and the establishment of a strong guiding ethos: to speed up the pace of scientific discovery. James is particularly interested in developing innovative equipment and improving the accessibility of new materials for solution-processable photovoltaics and hybrid organic-inorganic devices. Dr. Alastair Buckley - Technical Director Alastair is a lecturer of Physics at the University of Sheffield, specialising in organic electronics and photonics. He is also a member of the EPMM research group with a focus on understanding and applying the intrinsic advantages of functional organic materials to a range of optoelectronic devices. Alastair’s experience has not been gained solely in academia; he previously led the R&D team at MicroEmissive Displays and therefore has extensive technical experience in OLED displays. He is also the editor and contributor of "Organic Light-Emitting Diodes" by Elsevier. Our Research Scientists Our research scientists and product developers have significant experience in the synthesis and processing of materials and the fabrication and testing of devices. The vision behind Ossila is to share this experience with academic and industrial researchers alike, and to make their research more efficient. By providing products and services that take the hard work out of the device fabrication process, and the equipment to enable accurate, rapid testing, we can free scientists to focus on what they do best - science. Customer Care Team The customer care team is responsible for the customer journey at Ossila. From creating and providing quotes, through to procurement and inventory management, the customer care team is devoted to providing first class customer service. The general day to day responsibilities of a customer care team member involves processing customers orders and price queries, answering customer enquiries, arranging the shipment of parcels and notifying customers of updates on their orders. Collaborations and Partnerships Please contact the customer care team for all enquires, including technical questions about Ossila products or for advice on fabrication and measurement processes. Location and Facilities Ossila is based at the Solpro Business Park in Attercliffe, Sheffield. We operate a purpose-built synthetic chemistry and device testing laboratory on site, where all of our high-purity, batch-specific polymers and other formulations are made. This is complemented by a dedicated suite of thin-film and organic electronics testing and analysis tools within the device fabrication cluster housed in a class 1000 cleanroom in the EPSRC National Epitaxy Facility in Sheffield. All our electronic equipment is manufactured on-site.